Old-fashioned Values

& Outstanding Service

Troymill Wood Products is one of the Midwest’s largest providers of pallets, crates and manufactured wood products to industry!

Troymill Wood Products

We Got Wood

Located in the heart of the Amish community of Middlefield, near Cleveland Ohio, Troymill is one of the largest pallet and industrial lumber companies in the Midwest.

From wooden pallets and boxes, to industrial lumber and grooved stock, Troymill maintains a huge inventory of lumber to ensure we are ready to support your business as a reliable supplier of manufactured wood products.

Troymill customers know that their pallet, lumber, crating and specialty product needs will be met, 24/7/365

Wooden Pallets & Crates—Custom & Standard Loads

Troymill turns out thousands of pallets every day on our automated lines—stringer or block style, heat-treated or plain—so Midwest shippers can count on consistent quality and on-time truckload delivery.

What we build

Standard 48 × 40 GMA pallets ready to ship by the truckload

Custom sizes & industrial skids matched to odd footprints or heavy loads

Block or stringer construction in hardwood or pine

ISPM-15 heat-treated options (never pressure-treated) for export compliance

Branding, paint stripes, stenciling, or other ID marks on request

When you partner with Troymill for pallet supply, you can expect:

Full or mixed loads priced competitively and scheduled to your dock rhythm

48′ & 53′ flatbeds, dry vans, or box-truck deliveries from our own fleet

Design support from veteran pallet engineers—over 50 years of woodworking know-how

Scalable capacity to cover seasonal surges without sacrificing lead time

Ready for a pallet program that keeps production rolling? Request a quote.

Industrial Lumber—Hardwood & Pine at Manufacturing Scale

Troymill mills, kiln-dries, and stocks hardwood, pine, and sheet goods on our 50-acre Ohio campus, maintaining deep, ready-to-ship inventory for fast truckload delivery across the Midwest.

What’s on hand

- Hardwood: oak, maple, poplar & more (random-length or cut-to-size)

- Softwood: spruce & southern yellow pine dimension lumber

- Panel Products: plywood and OSB for crating

- ISPM-15 heat-treated: export-ready material (never pressure-treated)

Why high-volume buyers choose Troymill

- Largest hardwood dunnage inventory: stable supply even during shortages

- Integrated sawmill + heat-treat kilns: fewer hand-offs and faster lead times

- Own fleet of flatbeds & vans: dependable, on-time delivery across the Midwest

- Three generations of expertise: guidance that keeps your line moving

Ready to receive Industrial Lumber pricing? Request a quote today.

Pre-Cut Pallet Wood — Cut-to-Length Deck Boards & Stringers, Ready to Nail

Troymill mills, kiln-dries, and precision trims hardwood and pine components, so your pallet line can skip the saw work and stay focused on assembly.

What we supply

Deck boards — ½- to 1-inch thick, trimmed to your exact length with optional chamfers

Stringers / runners — notched or solid, grooved for automated nailers, heat-treated on request

Half-pallet and block pallet components — custom widths for 4-way or 9-block builds

Species options — durable oak, maple, and poplar; economical spruce or southern yellow pine

Packaged by kit or by piece — banded bundles labeled for fast line-side spotting

Why pallet builders count on Troymill

Production speed — truckload volumes arrive cut and kiln-dried, no on-site trimming or waste handling

Tight tolerances — CNC saws deliver ±1/16″ accuracy; boards feed straight into automated nailers

Consistent, covered inventory — components stay clean and dry until we load our sky-blue trailers

Own fleet & flexible loads — mix deck boards and stringers on the same flatbed to balance stock

Three generations of expertise — we flag yield improvements and spec tweaks that cut your cost per pallet

Ready to keep your nail line running wide open? Request a pre-cut lumber quote.

Dunnage & Cribbing — Shock-Absorbing Boards and Blocks for Heavy Loads

Troymill kiln-dries and machines hardwood dunnage boards and solid cribbing blocks that cushion equipment, level pallets, and brace oversized cargo, keeping freight safe from impact, moisture, and road shock.

What we supply

Standard & custom boards / blocks — square-cut, chamfered, notched, or wedge-shaped

Precision banding-groove dunnage for secure strapping and even weight distribution

Solid cribbing blocks & timbers up to 12″ x 12″ for rigging, jacking, and stacking heavy machinery

Kiln-dried or ISPM-15 heat-treated options for export or indoor storage

Hardwood species chosen for strength (oak, maple, hickory) or economical pine when weight allows

Why high-volume shippers choose Troymill

Consistent truckload inventory — no gaps in your packaging line

Exacting sawmill tolerances — boards stack true, blocks sit square, straps lie flat

Fast turnaround from our 50-acre Ohio facility to Midwest and Mid-Atlantic docks

Clean, covered storage keeps stock dry and debris-free until loading

Own fleet of sky-blue flatbeds & vans ensures on-time delivery you can track

Three generations of lumber expertise — solutions built for real-world load stresses

Need dunnage or cribbing that won’t let your cargo or your schedule slip? Request a custom quote.

Specialty Products — Custom Wood Fabrication for Your One-Off Challenges

Not every load fits a standard pallet or crate. Troymill’s fabrication shop combines CNC accuracy, Amish craftsmanship, and truck-load capacity to turn hardwood and pine into purpose-built solutions that keep odd-shaped, high-value cargo secure—from steel coils to massive machine frames.

What we build

Coil racks & curved saddles — 4×4, 6×6, or custom radius; kiln-dried and paint-striped for quick ID

Hardwood wedge blocks & chalks — precision-cut angles for rail, barge, or flatbed bracing

Pipe and machinery skids — heavy-duty bases up to 20 ft long, engineered in PDS and heat-treated on request

Ramp and threshold boards — laminated hardwood panels for smooth warehouse transitions

Corner boards, cleats & braces — laminated clips or solid hardwood, cut to exact line-side dimensions

Any oddball fixture you can sketch—if it’s wood and ships in bulk, we can mill it

Why shippers choose Troymill for specialty builds

Extreme customization at volume — prototypes or thousand-piece runs on the same automated lines

Clean, covered inventory — components stay dry and debris-free until your truck arrives

Modern tech + Amish craft — CNC routers and automated nailers guided by three generations of woodworking skill

Own fleet of sky-blue flatbeds & vans — loaded each morning for on-time Midwest and Mid-Atlantic delivery

ISPM-15 heat-treat & kiln-dry in-house — export compliance without third-party delays

Sustainably sourced lumber — managed-forest hardwood; every off-cut reused as fuel or bedding

Ready to solve a packaging problem that standard pallets can’t touch? Request a custom quote

A Pallet Supplier Built for Reliable Volume

When pallets are part of your production rhythm, you need a supplier that can keep up. Troymill produces pallets at scale on automated lines, in standard GMA or custom skids, with options for heat treatment and identification marks when needed.

What you can count on from Troymill pallet supply:

- Truckload-ready availability for standard and custom pallet programs

- Block or stringer builds in hardwood or pine, built to the demands of industrial shipping

- ISPM-15 heat-treated options for export compliance (never pressure-treated)

- Delivery that matches your schedule, including 48’ and 53’ trailers from Troymill’s fleet

- Engineering support for odd footprints, heavy loads, and seasonal surges

Learn more before you choose a supplier:

The Troymill Difference

With more than five decades of experience in the lumber and pallet industry, we understand that change is the only constant.

Our success hinges on a steadfast dedication to delivering the optimal customer experience. When integrity, diligence, and outstanding service converge with state-of-the-art technology, the inevitable outcome is contented Troymill customers. Reach out to us for an exceptional encounter with top-notch products and service in your acquisition of lumber, wood products, and wholesale pallets.

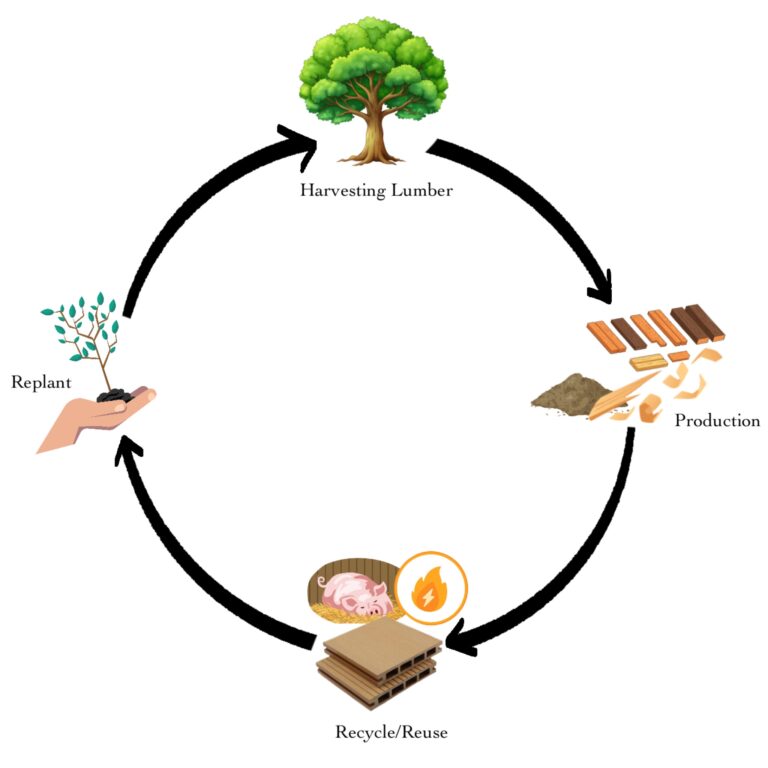

We extend the life of our products and reduce environmental impact by reclaiming and repurposing used pallets for continued use.

Every byproduct, from sawdust to cutoffs, is reused in secondary manufacturing or energy production, ensuring nothing goes to waste.

In addition to re-using 100% of our wood waste, we recycle all metal, plastic, and corrugated materials—keeping nearly all manufacturing byproducts out of landfills.

Most of our wood comes from FSC-certified suppliers, verified through annual audits to protect forests for future generations.

Sustainability

We implement sustainable lumber practices that ensure our manufacturing processes have a minimal impact on the environment.

Wood Packaging – Essential and Sustainable